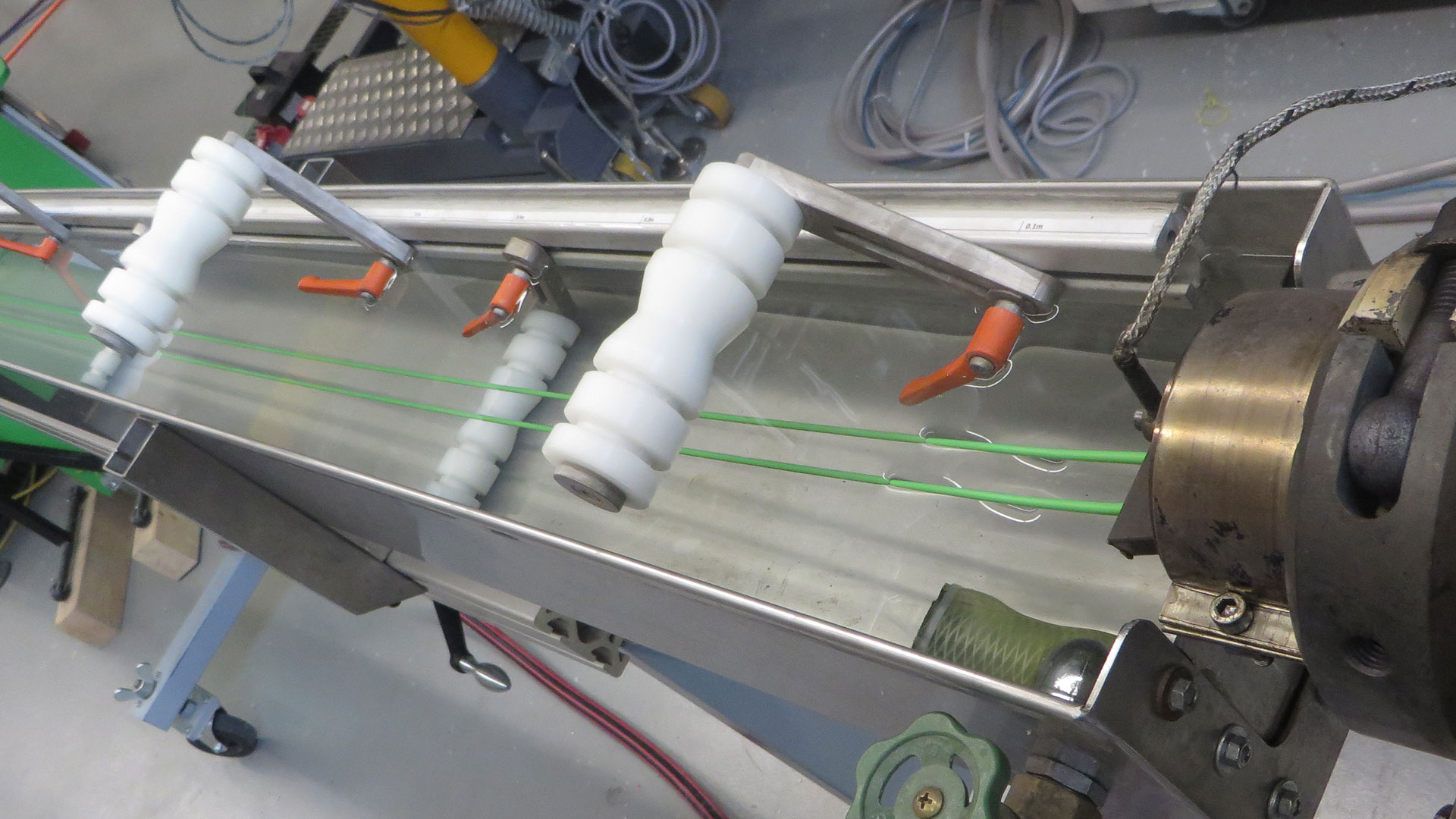

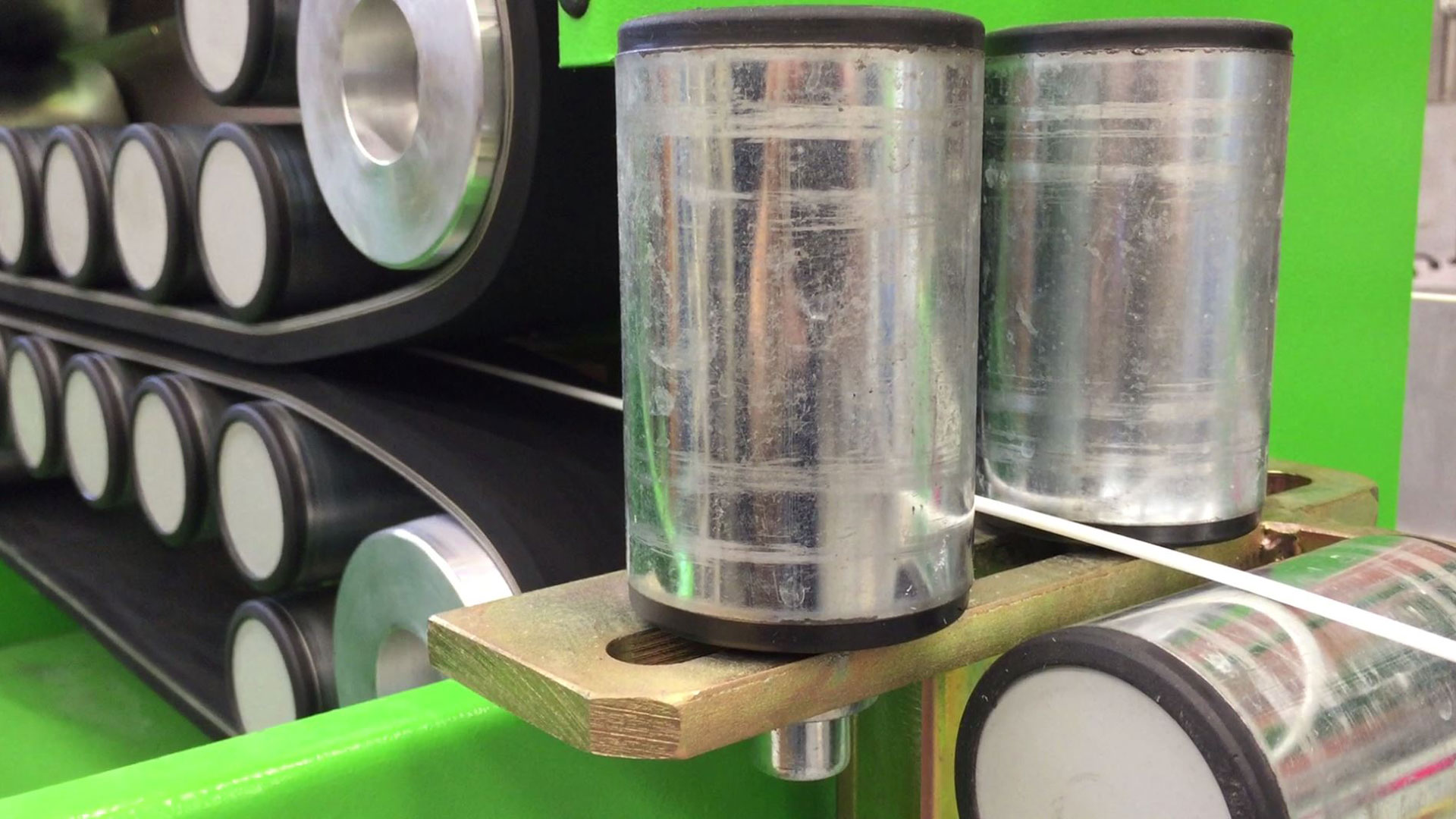

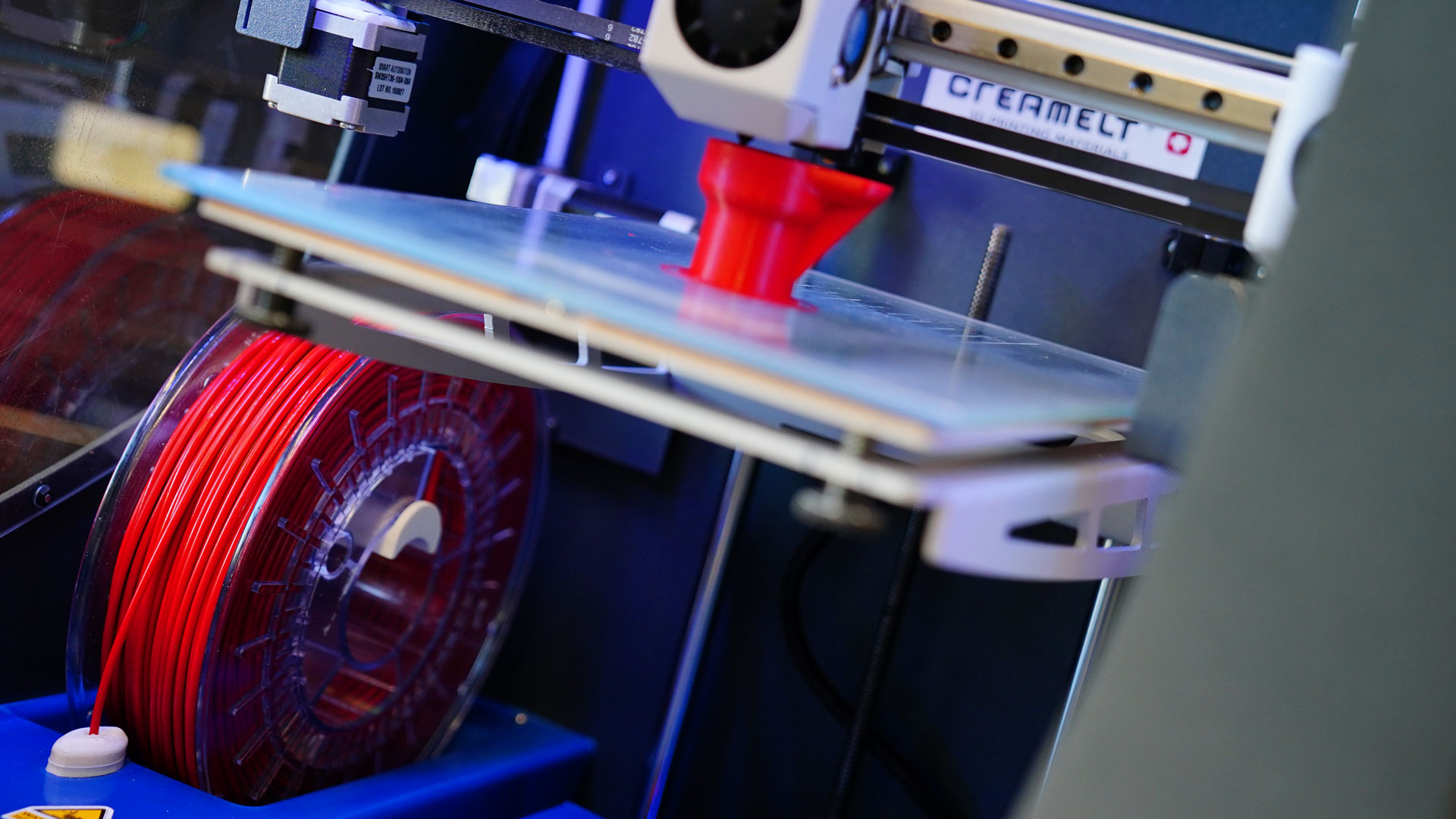

CUSTOMIZED FILAMENTS

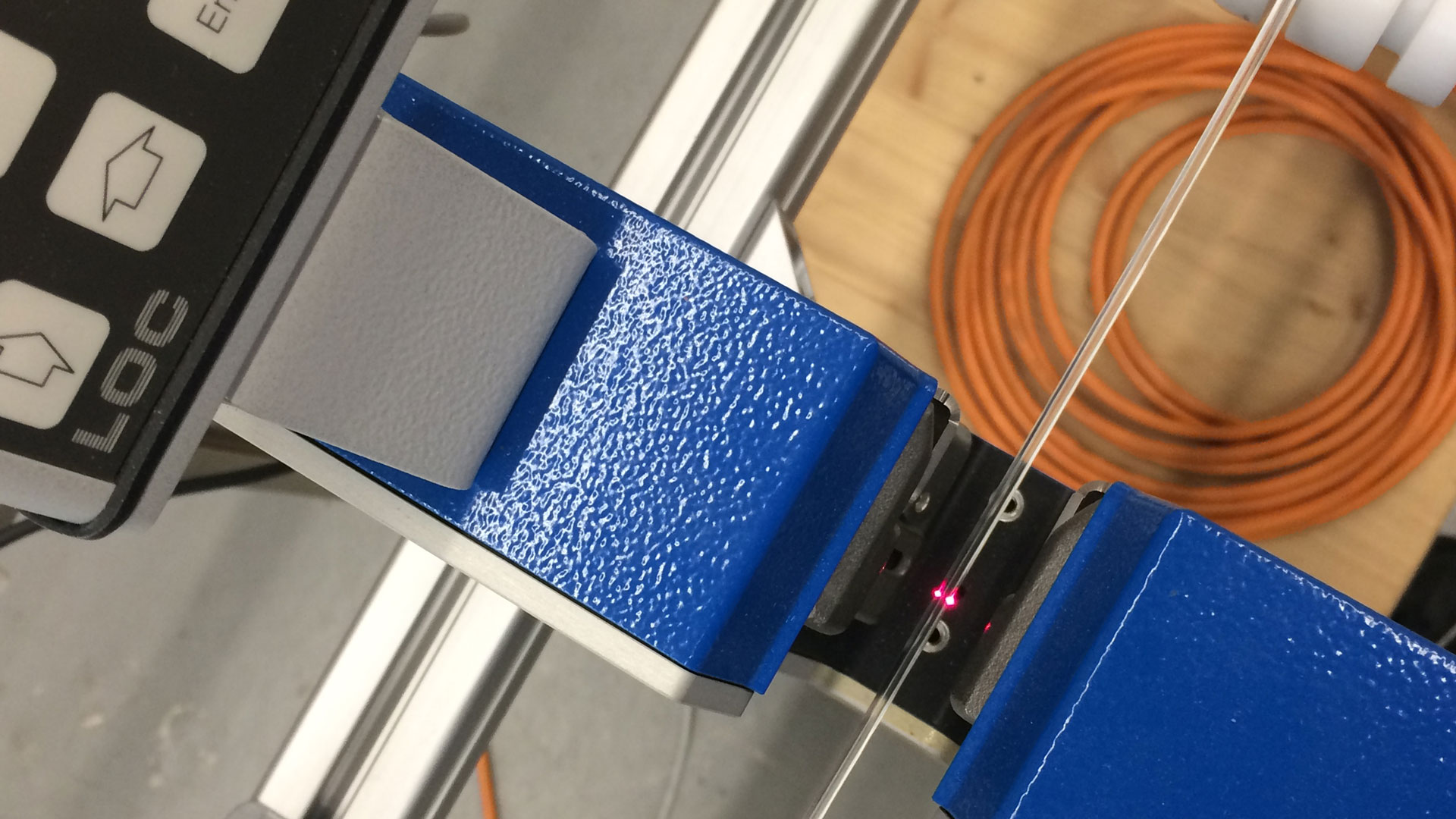

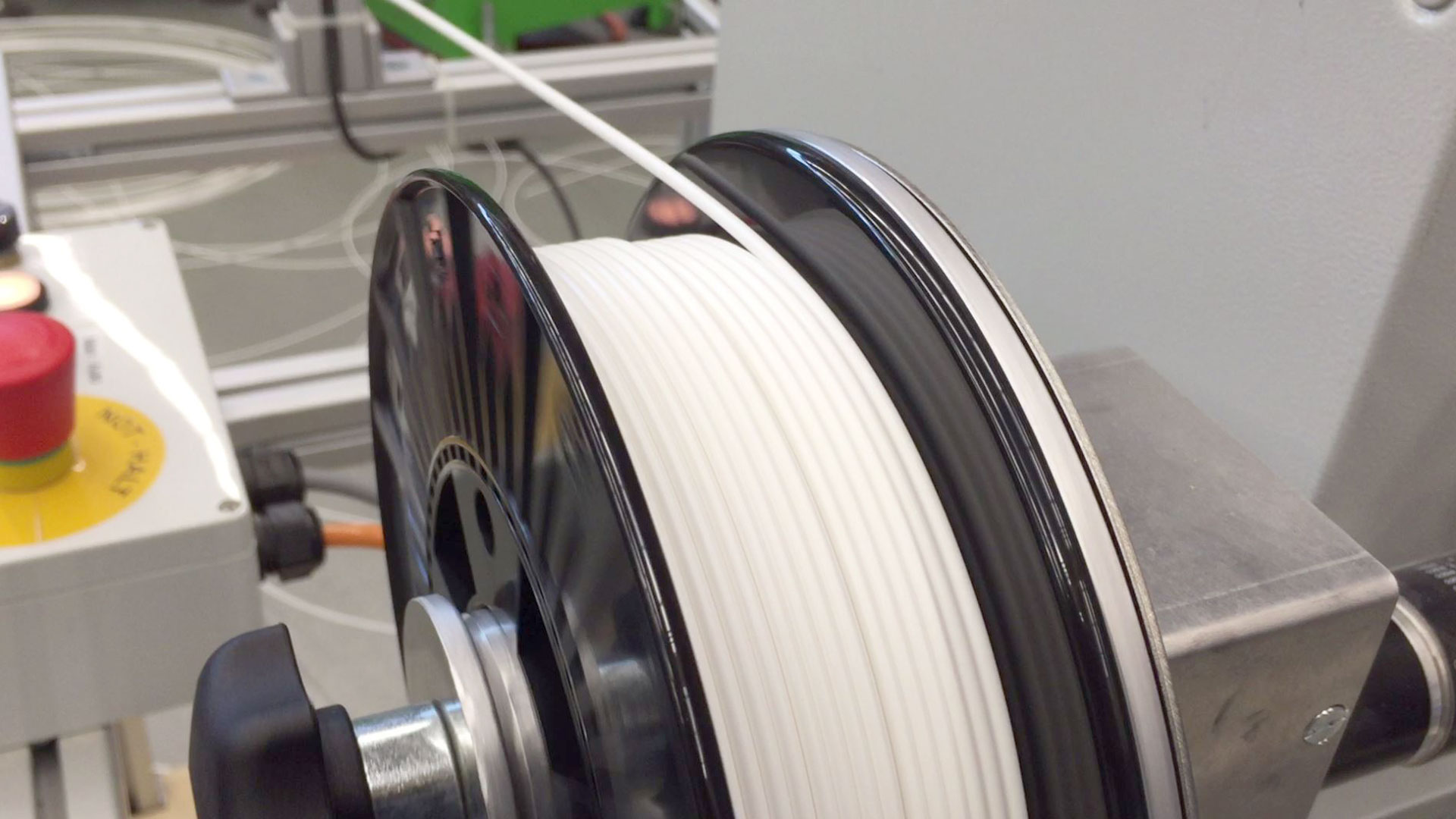

Next to our standard materials we also produce filaments according to customer specific needs. Our high-quality production line is suitable for the extrusion of filaments made from nearly every thermoplastic polymer. Material properties can be modified and adapted to individual needs by using the compounding process.