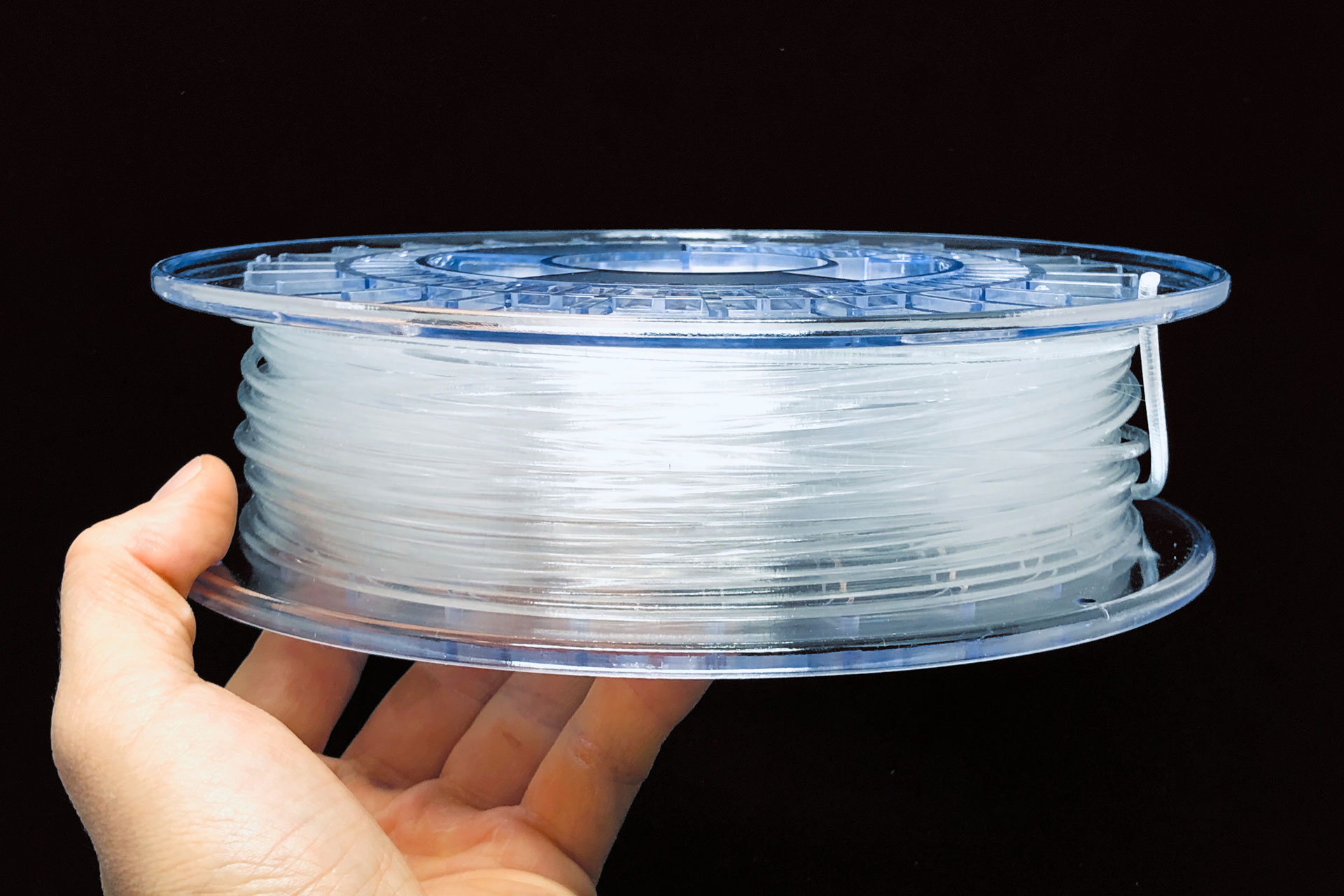

CREAMELT® COC

DESCRIPTION

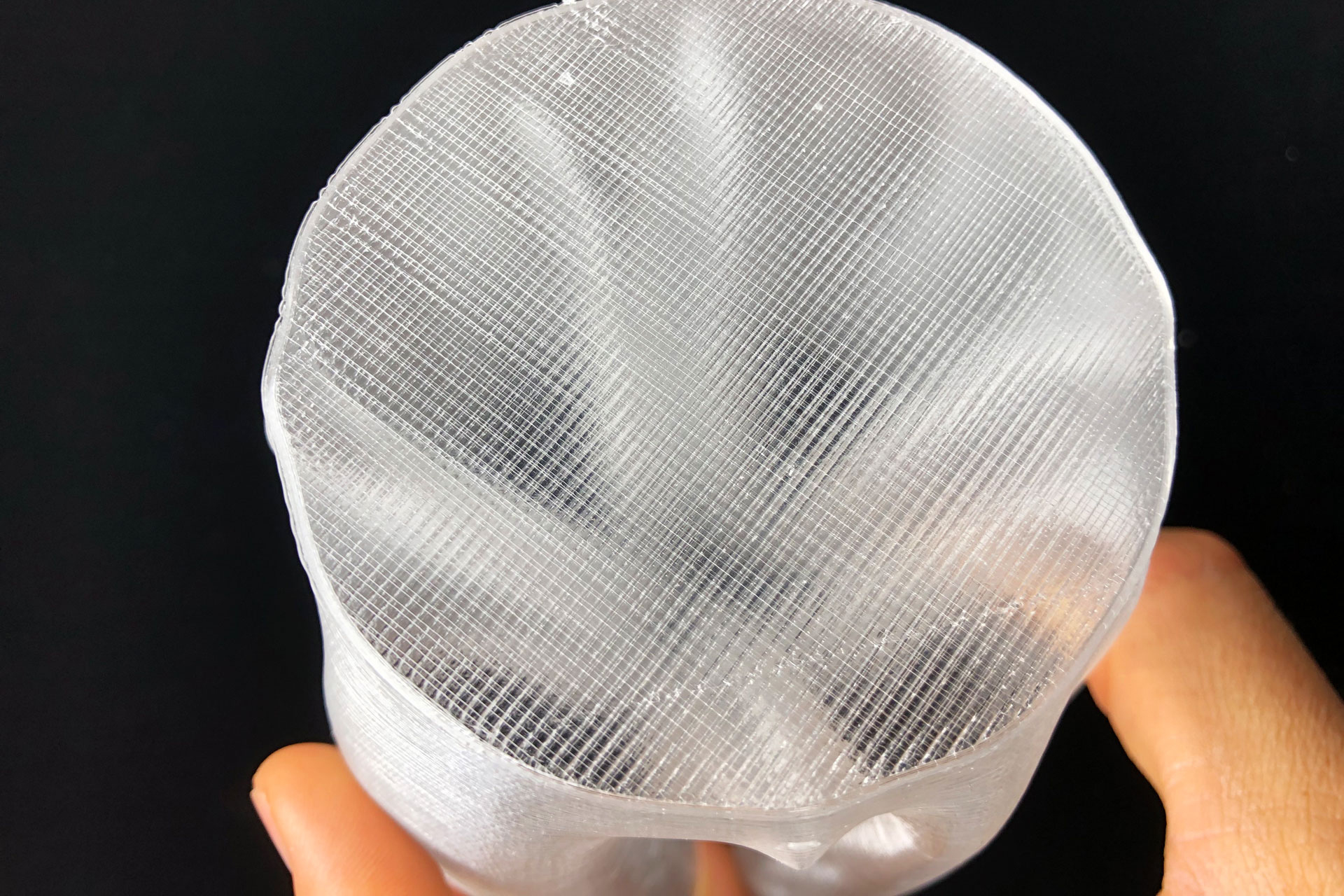

CREAMELT® COC is a transparent filament made from Cyclic Olefin Copolymer (COC). COC is typically used for optical applications, medical devices or pharmaceutical packaging. It offers many benefits over other polymers: biocompatibility, transparency, very low water absorption, good barrier properties, excellent resistance to acids and alkalis as well as many sterilization processes. It has very good melt processability and can be printed on standard FFF 3D printer. The amorphous polymer doesn’t warp and has an excellent print performance. Printed parts are translucent and have excellent mechanical properties.

PRINTING GUIDELINES

PRINTING TEMPERATURE = 240…250 °C

PLATFORM TEMPERATURE = 80…90 °C

PRINT SPEED = 40…150 mm/s

MECHANICAL PROPERTIES )*

TENSILE MODULUS = 2600 MPa

TENSILE STRENGTH = 63 MPa

TENSILE STRAIN AT YIELD = 4.5 %

CHARPY IMPACT STRENGTH = 20 kJ/m^2 (ISO 179 / 1eU)

CHARPY NOTCHED IMPACT STRENGTH = 2.6 kJ/m^2 (ISO 179 / 1eA)

* as measured by injection molded tensile bars at 23°C

(Note: Values shown are based on material suppliers technical data sheet. They are not measured on 3d printed test specimens.)

PHYSICAL & THERMAL PROPERTIES

DENSITY = 1010 kg/m^3

MELT TEMPERATURE = 190…250 °C

GLASS TRANSITION TEMPERATURE = 78 °C

HEAT DEFLECTION TEMPERATURE HDT/B (0.45 MPa) = 75 °C

WATER ABSORPTION = 0.01 % (ISO 62)

WATER VAPOR PERMEABILITY @ 23°C, 85% RH = 0.025 g*mm/(m^2*day) (DIN 53122)

DEG. OF LIGHT TRANSMISSION = 91% (ISO 13468-2)

(Note: Values shown are based on material suppliers technical data sheet. They are not measured on 3d printed test specimens.)

Available Colors