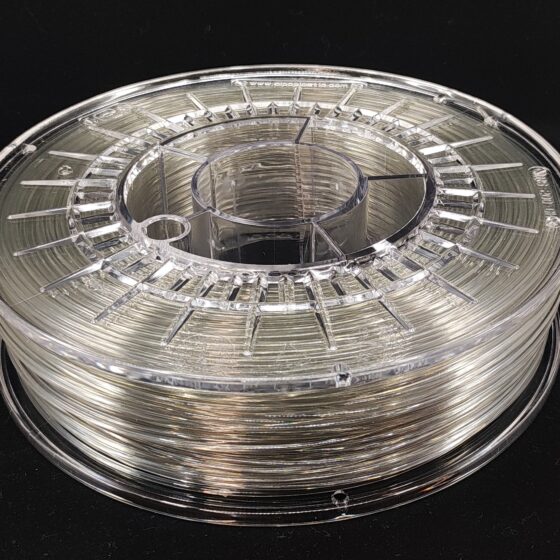

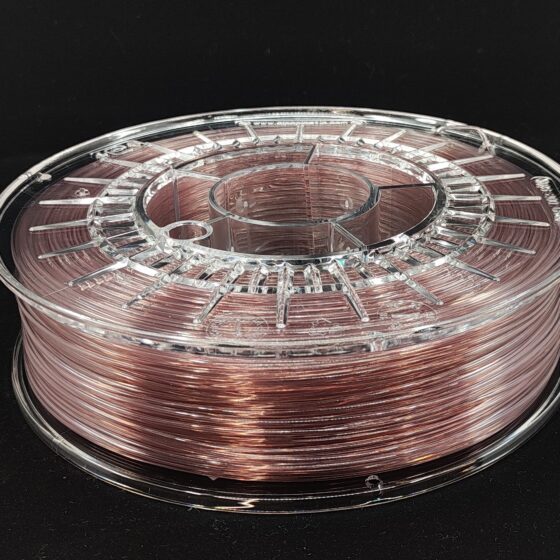

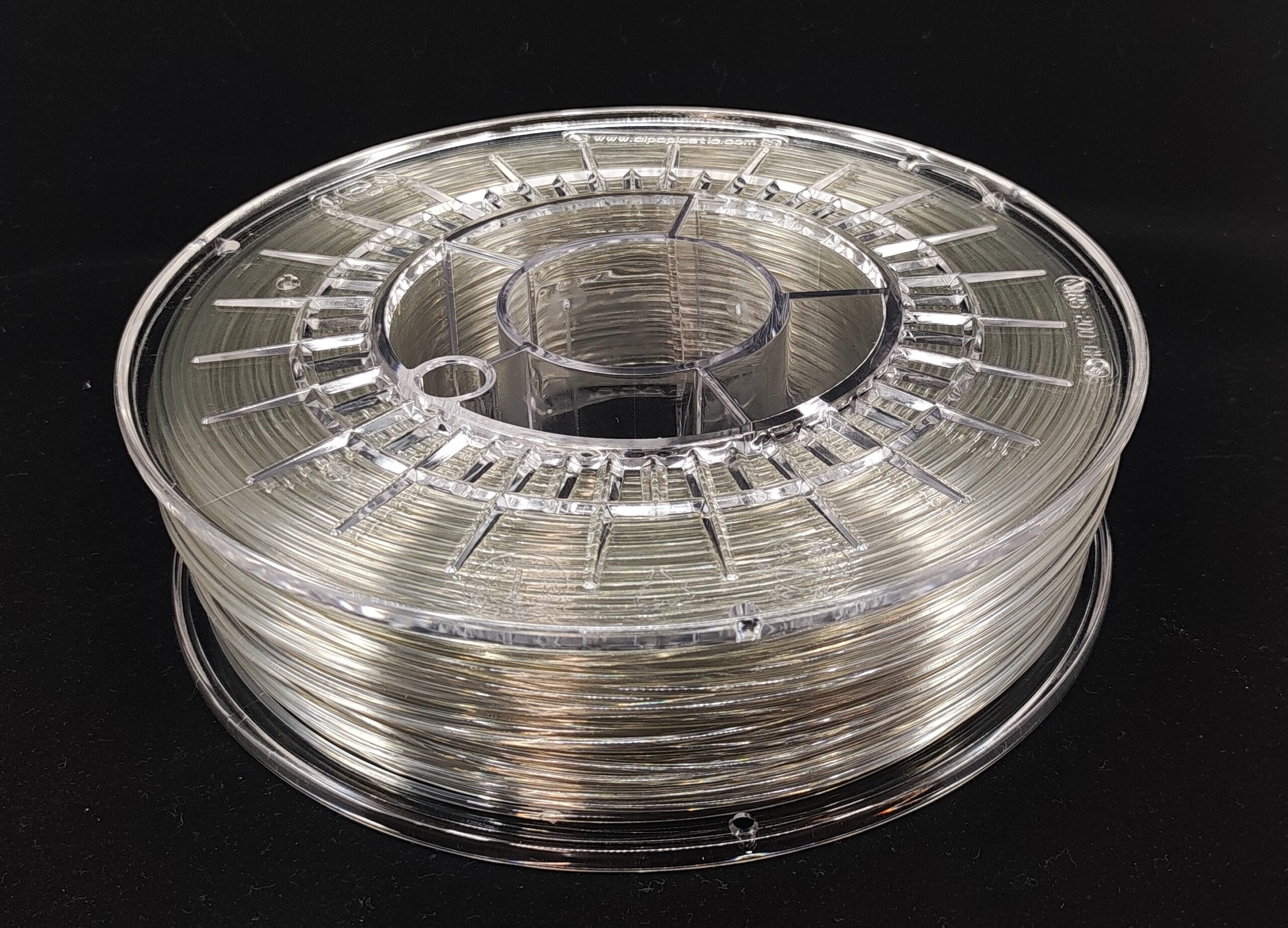

CREAMELT® rPET fifty

DESCRIPTION

CREAMELT® rPET fifty is a filament made from 100% recycled PET (polyethylene terephthalate). It consists of 50% industrial multilayer PET-G/PET and 50% ocean-bound PET waste from #tide. rPET fifty gives you the ability to design and print durable parts with great chemical and heat resistance made from recycled materials and is a sustainable alternative to virgin material. Its distinctive appearance is great for interior design objects such as lampshades or vases.

Since PET-A is a polycondensate and thus a hygroscopic material that absorbs a lot of moisture from the environment, pre-drying before printing and storage in a dry storage box during printing is strongly recommended. This is the only way to prevent bubble formation on the printed component and maximize print quality.

PRINTING GUIDELINES

PRINTING TEMPERATURE = 255…265 °C

PLATFORM TEMPERATURE = 80…90 °C

PRINT SPEED = 40…60 mm/s

NOZZLE SIZE = Ø0.4…0.8 mm

FILAMENT STORAGE DURING PRINT = Drying Box

DRYING RECOMMENDATION = 100 °C/ 4-6h

MECHANICAL PROPERTIES

TENSILE MODULUS (1) = 1650 MPa

TENSILE STRENGTH (1) = 49 MPa

ELONGATION AT BREAK (1) = 3 %

IMPACT STRENGTH (2) = 115 kJ/m^2

(1) as measured by printed tensile bars DIN EN ISO 527 (1BA)

(2) as measured by printed impact samples DIN EN ISO 179/1 charpy unnotched

(Note: Values shown are based on material suppliers technical data sheet. They are not measured on 3d printed test specimens.)

PHYSICAL & THERMAL PROPERTIES

DENSITY = 1150 kg/m^3

MELT TEMPERATURE = 250…260 °C

GLASS TRANSITION TEMPERATURE = 75…80 °C

CRISTALLIZATION POINT = 195…205 °C